There are many types of surface treatments used for both metals and plastics. The best one depends on the polymer/metal type and intended end use of the substrate in question. High-energy plastics have a higher surface energy, and so they bond better. The choice of surface treatment will vary, so make sure you choose the right method for your product so you get the results you are seeking.

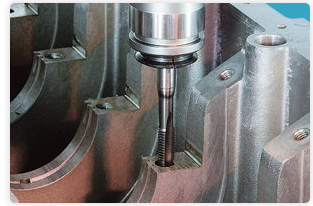

High-energy surface treatments include corona, plasma, and flame. They alter the molecular structure of a surface to increase adhesion properties. Some of the types of surface treatments are electrochemical, physical, and chemical, with a popular example being electroless nickel plating.

Another type of surface treatment improves wettability. It increases the material’s surface energy and creates ideal conditions for printing or bonding. Plastic syringe barrels can be treated prior to bonding with a stainless steel needle, plastic needle hubs, and adhesive labels on plastic bottles. Using a surface treatment improves adhesion of inks and other materials. Further, surface treatments improve the adhesion properties of plastic materials and allow printing on them.

Depending on the application, surface treatments may affect the durability of a product. Using excessive surface treatment can cause the material to fail, which wastes time and money. Additionally, excessive surface preparation may make a product unstable and void of adhesion. By specifying a treatment that is beyond the capabilities of the production process, engineers are taking a risk by extending the product’s cycle time.

Plasma surface treatment is a common treatment used in various industrial sectors. It works by exchanging airborne and organic contaminants with carbon dioxide or water vapour. It also activates a clean surface by replacing inert hydrocarbon bonds with reactive groups. Plasma surface treatments increase the surface energy, which is important for adhesion and bonding to adhesives. If you’re not sure which type of surface treatment is right for your application, take a look at the different methods available and speak to experts. For more on Surface Treatments by visiting a site such as https://www.poeton.co.uk/standard-treatments/electroless-nickel-plating/

One of the main reasons for using surface treatments is to extend the life of a product. When you reduce the wear and tear risk of an object, it will last longer. This is precisely what surface treatments offer – to toughen and make more durable thus extending the life cycle of the substrate of a product. It also makes maintenance less of an issue and less expensive.