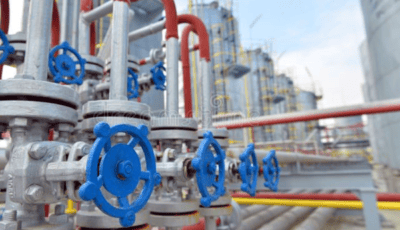

Industrial valves control the flow of fluids and relieve pressure in piping systems. They are available in a multitude of sizes and designs to satisfy a wide range of industrial needs, but do you know how to choose the right valves for your purposes?

To ensure the valves you select are appropriate for your needs and will provide reliable service, there are five important factors you must consider. Let’s take a look at them:

1. End connection

Valves are installed between the existing pipework and are therefore supplied with different end connections to ensure compatibility with your system. Using the wrong valve connection threatens the safety and efficacy of your system, so always ensure you select the right end connection.

2. Maintenance requirements

Stock valves must be appropriately maintained to ensure the longevity of your system. They must also fit in with your existing maintenance regime, so look for valves with maintenance periodicities that complement your existing maintenance schedule rather than introducing additional work and cost for little benefit. Suppliers such as orseal.com can help you to select the appropriate products for your needs.

3. Safety mechanisms

A valve failure could result in a leak, which can quickly depressurise your system and cause major damage to mechanical components Always look for industrial valves with appropriate safety mechanisms and safeguards to protect your business operations.

4. Environmental conditions

Industrial environments put valves under extreme pressure, as they are routinely exposed to high temperatures, humidity, and acidity. These all accelerate the process of corrosion. For this reason, you should select valves with protected surfaces to ensure their longevity in your operating environment.

5. Correct installation

Finally, it is of little use buying the right valve for the job if it is not correctly installed. Always install valves to the manufacturer’s guidelines, using the correct torque and following test procedures to ensure they are correctly installed before fully pressurising the system.

By considering these five points, you will be well-placed to enjoy excellent durability, operational efficiency and operator safety once your new valves are fitted.